High drawing speed, high manganese steel type special dry material

At present, most of the intermediate ladle working liner dry material used in steelmaking is magnesium dry material. But magnesium dry material mainly used raw materials for magnesium sand, magnesium sand using sintered magnesite or electrofusion magnesite method of production, sintering and smelting costs are very high, and magnesium sand bulk density is high (generally 3.2g/cm3), the production of dry material bulk density is generally 2.4g/cm3 or so. Because of the high thermal conductivity of magnesium dry material, in the steelmaking process requires a higher molten steel temperature, baking intermediate package of about 800 ° C to make up for the loss of heat, greatly increasing the cost and waste of resources.

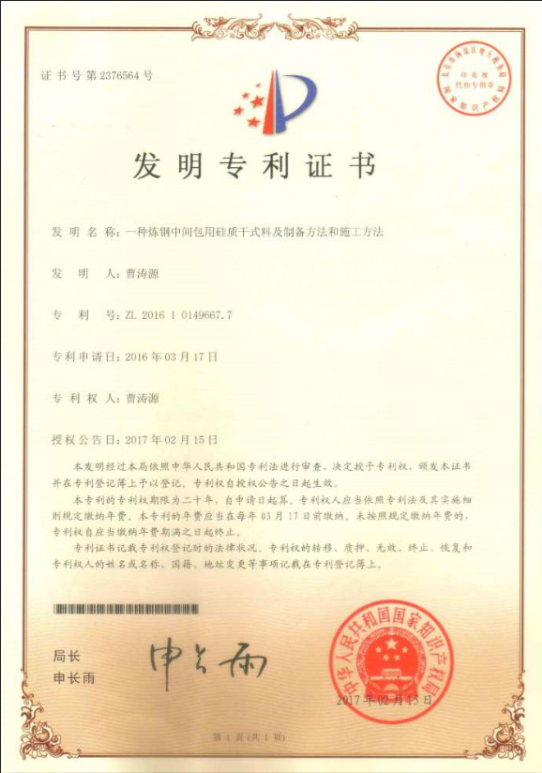

Luoyang City Kelder Refractories Co., Ltd. uses the main material with silica sand, additional other materials produced by the neutral dry material of the bulk density is generally about 2.0g/cm3, with good thermal insulation properties, and good use of the effect of energy saving and environmental protection. Obtained the national invention patent: (Patent No. CN105777158A), and achieved significant social and economic benefits.

Silicon dry material patent certificate

Luoyang City Kelder Refractories Co., Ltd. continues to pursue and innovate and does not stop.

Starting in 2018, with the increase of national standards for seismic design of buildings. The market demand for a large number of HRB400, HRB400e steel grades. Thus steel smelting generally increased manganese content, the original refractory design standards need to be further improved and optimized in order to meet the manganese content increase on the refractory stronger scouring resistance, erosion resistance, and with the production of the compact speed up, the pulling speed is generally increased, but also put forward more demanding requirements for the refractory material.

Luoyang City Kelder Refractories Co., Ltd. according to the actual situation of steel mills, the establishment of a specialized group, and scientific and technological institutions, after repeated experiments in the laboratory and the use of steel mills, in August 2018, research and mature put on the market of the new type of neutral dry material, in Shanxi, 3 steel mills, Xinjiang, 2 steel mills, as well as Hebei Langfang, a steel plant, Xuzhou, and other steel mills used to obtain a good use of the results.

Solve the high pulling speed, high manganese content of the intermediate packet work lining materials, scour erosion serious, many steel mills have not been able to solve the problem, so that the intermediate packet of high manganese steel species life significantly improve the labor intensity of the workers to reduce the production efficiency is greatly improved.

Since August 2018 the company's new research and development of a new type of neutral dry material in the original batch use of various steel mills, the use of the effect shows that: greatly improve the life of the intermediate package, steel 400E service life of 40-50 hours, to solve the problem of steel mills have been unable to solve. Now in the market to promote the use of a large number.

The new neutral dry material has the following advantages:

1、With the advantage of cost-effective

2、Simple baking, easy construction.

3、Compared with the previous generation of dry material, it has the characteristics of small volume expansion and high demolding strength.

4、Excellent heat preservation performance, the second baking has good strength in high temperature.

5、Significantly improve erosion and scour resistance. For Q235 and other low manganese steel type significantly improve the service life. For HRB400, HRB400e solves the uneven scouring and improves the service life.

Luoyang Kelder Refractories Co.

Contact: Mr. Cao

Tel: 13903798882

Work e-mail: kerdnc@126.com

Company website: www.lykerd.com